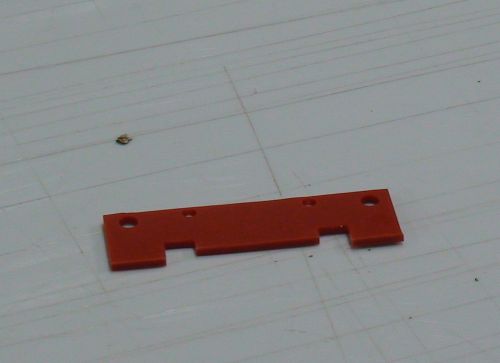

Rubber Gaskets

Rubber gaskets are one of the most common types of gaskets used. A rubber gasket can be found in almost every household product that has moving parts. They are also common in automotive and industrial applications.

Rubber gaskets have a great number of advantages that make for an excellent gasket. It has a spongy characteristic that allows it to mold in between machine parts creating a snug fit. It is also excellent at blocking fluids from passing through. Finally, rubber gaskets are excellent at dampening machine vibrations allowing the machine to have a longer life. Your Apex Die and Gasket representative will be more than glad to talk to you about rubber gaskets for your company.

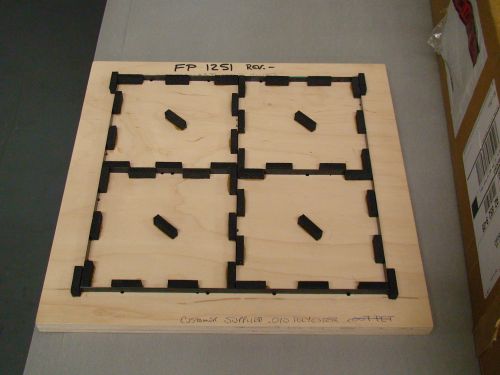

Apex Die and Gasket has been developing high-quality rubber gaskets for a wide variety of industries since 1989. Some of those industries include:

- Electronics

- Aerospace

- Material Distributors

- Assembly Plants

- Inventors

- OEM Industries

Each client that comes to us for the development of a rubber gasket goes through a complete needs analysis determining the specific requirements for the gasket and the environment in which it will be used. This information is valuable as it helps create a design that will meet your requirements.

Types of Rubber Gaskets

The advantage of rubber gaskets is that they can be made from a wide variety of rubber products. As part of the consultation on the development of your gasket, we will determine the type of rubber that will handle your requirements. Some of the types of rubber that Apex Die and Gasket uses to create gaskets include:

- Neoprene (Solid or Sponge)

- EPDM

- Urethane

- Viton

- SBR

- Pure Gum

- Silicone

Contact Apex Die and Gasket

Call Apex Die and Gasket today to learn how we can help you in the development of rubber gaskets. In the Phoenix Metropolitan area, call us at 480-894-1112. You can also reach us with any rubber gasket questions through our Contact Us page.